Are you in search of a reliable PBT Heat-resistant Modifier manufacturer? Look no further, as we introduce you to YC-012, a groundbreaking powder manufacturer dedicated to enhancing the performance of PBT materials. With a focus on delivering high-quality products, YC-012 offers bulk powder solutions for industries seeking to optimize their heat-resistance properties.

Why Choose YC-012 as Your PBT Heat-resistant Modifier Manufacturer?

What sets YC-012 apart from other suppliers?

Looking to boost the heat resistance of your PBT materials efficiently?

YC-012 delivers exceptional results by incorporating state-of-the-art technology in the production of their heat-resistant modifiers. With an extensive expertise in polymer science, YC-012 has developed a remarkable solution that enhances the stability and durability of PBT materials, while effectively combating high temperatures.

Elevating PBT Material Performance

How does YC-012 improve the heat resistance of PBT materials?

Can YC-012 help in achieving higher material strength?

The proprietary formula used by YC-012 acts as a barrier against heat, preventing PBT materials from losing their structural integrity when exposed to elevated temperatures. By incorporating YC-012’s heat-resistant modifier, PBT materials gain exceptional mechanical strength and retain their shape even in extreme environments. This breakthrough technology allows industries to explore new possibilities and expand the applications of PBT materials in demanding settings.

Bulk YC-012 Powder: The Key to Seamless Integration

Why should you opt for bulk YC-012 powder?

How does YC-012 facilitate large-scale production processes?

With a commitment to meeting the growing demands of industries, YC-012 provides bulk YC-012 powder, enabling manufacturers to seamlessly integrate it into their production workflows. The easy dispersibility and compatibility of YC-012 with PBT materials ensure a hassle-free incorporation process, saving time and resources. By partnering with YC-012, businesses can significantly enhance the heat resistance of their products without compromising on efficiency or scalability.

Choosing YC-012: Your Trusted PBT Heat-resistant Modifier Supplier

Seeking a reliable PBT Heat-resistant Modifier supplier?

Where can you find high-quality YC-012 powder for your industry needs?

By choosing YC-012 as your PBT Heat-resistant Modifier supplier, you gain access to a superior product that consistently exceeds industry standards. YC-012 prioritizes quality control throughout the manufacturing process, ensuring that each batch of powder meets stringent criteria before reaching your hands. With YC-012, you can achieve the desired heat resistance enhancement for your PBT materials without any compromise on reliability or performance.

Wholesale YC-012 Powder: Elevating Your Business Success

Interested in wholesale YC-012 powder for your business?

How can YC-012 powder contribute to the success of your projects?

YC-012 offers wholesale options for businesses looking to incorporate heat-resistant modifiers into their projects on a larger scale. By obtaining YC-012 powder in bulk, industries can enjoy cost savings and ensure the consistent availability of this revolutionary solution. Partnering with YC-012 not only elevates your product offerings but also optimizes your business processes, setting you up for success in today’s competitive market.

In conclusion, YC-012 is a leading PBT Heat-resistant Modifier manufacturer that revolutionizes the performance of PBT materials. With their technology-driven approach and commitment to excellence, YC-012 provides bulk powder solutions, serving as a reliable supplier for industries seeking to enhance the heat resistance of their products. By choosing YC-012, businesses can unlock new possibilities and achieve superior material performance in demanding environments.

Looking for a versatile, high-performance plastic material that ticks all the boxes? Look no further than high strength PA6 plastics raw material. With its new style PA6 plastic particle, transparent grade reinforced polyamide, high viscosity polyamide fiber particles, and high toughness nylon 6 plastic granules, this raw material offers a perfect solution for your manufacturing needs.

Unveiling the Power of High Strength PA6 Plastics

High strength PA6 plastics, also known as polyamide 6, are renowned for their exceptional mechanical properties. These plastics are widely used in various industries due to their high tensile strength, impact resistance, and excellent wear properties.

New Style PA6 Plastic Particle: Innovation at its Finest!

With the introduction of new style PA6 plastic particles, the game has changed for the better. These particles bring even more versatility and freedom to your manufacturing process. The new style enhancements include improved molding flow, superior dimensional stability, and enhanced heat resistance. This means better control over your production and greater consistency in your final products.

Transparent Grade Reinforced Polyamide: Enhancing Aesthetics and Functionality

In industries where transparency is essential, such as automotive and consumer electronics, transparent grade reinforced polyamide steps up to the plate. This grade of PA6 plastics offers a unique combination of transparency, strength, and toughness. It allows you to design visually appealing products without compromising on performance.

High Viscosity Polyamide Fiber Particles: Optimal Strength and Durability

When it comes to applications demanding exceptional strength and durability, high viscosity polyamide fiber particles come to the rescue. These particles are specifically engineered to provide extraordinary mechanical properties and excellent resistance to chemicals and solvents. Whether you need to create robust industrial components or rugged consumer goods, this type of PA6 plastic is perfect for the job.

High Toughness Nylon 6 Plastic Granules: Unyielding Performance

For products that require high toughness and impact resistance, look no further than high toughness nylon 6 plastic granules. This type of PA6 plastic excels in challenging environments, offering exceptional tensile strength, stiffness, and resistance to abrasion. It’s the go-to choice when you need a material that can withstand the harshest conditions.

Raw Material of Plastic Granules: Driving Innovation Forward

High strength PA6 plastic raw material, in the form of granules, is the foundation for many innovative products. These granules provide a versatile starting point for various manufacturing processes, such as injection molding, extrusion, and blow molding. With its exceptional properties and ease of processing, this raw material empowers designers and engineers to create cutting-edge solutions.

In conclusion, high strength PA6 plastics raw material is a game-changer in the realm of plastics manufacturing. From the innovation of new style PA6 plastic particles to the versatility of transparent grade reinforced polyamide, this material offers endless possibilities. Whether you require high viscosity polyamide fiber particles or high toughness nylon 6 plastic granules, PA6 plastics have got you covered. Embrace the power of high strength PA6 plastics raw material and unlock a world of manufacturing possibilities!

A guide to protecting your luggage

In a humid environment, luggage often faces the problem of mold growth, which not only affects the appearance, but may also cause damage to the items inside. TOPONE Anti-mold Material Co., Ltd. specializes in the mold and desiccant industry and is committed to providing you with effective mold prevention solutions. Here are some practical mold prevention suggestions to help you protect your luggage.

1. Use mold-proof desiccant

Placing an efficient desiccant in your luggage, such as silica gel desiccant, can effectively absorb moisture and reduce humidity, thereby preventing mold growth. This desiccant can maintain a dry state in an enclosed space, ensuring that your items are not affected by moisture.

2. Clean your luggage regularly

Regularly cleaning your luggage, especially those corners that are prone to dirt and grime, can effectively reduce the chance of mold growth. Use a mild detergent to ensure that the interior of the luggage is dry before storing it.

3. The importance of the storage environment

Choosing a well-ventilated and dry storage environment is key. Avoid storing bags in damp basements or closed cabinets. Use a dehumidifier to keep the air dry.

4. Avoid long-term sealing

Storing bags in sealed containers for a long time will cause moisture to accumulate and increase the risk of mold growth. Open the bags regularly to allow air to circulate and keep them dry.

5. Choose high-quality materials

When choosing bags, consider using anti mold packing paper as a lining material to effectively enhance the anti-mold effect. This material not only provides protection, but also improves the overall user experience.

With the above simple measures, you can effectively prevent bags from mold and extend their service life. The professional anti-mold products provided by TOPONE Anti-mold Material Co., Ltd. will be the best choice for your bag protection. Choose our solutions to keep your bags dry and fresh at all times!

Do you learn about the importance of moldproofing items?

In a humid environment, mold not only affects the appearance of items, but can also be a health hazard. TOPONE Anti-mold Material Co., Ltd. specializes in the moldproofing and desiccant industry and is committed to providing you with efficient moldproofing solutions. Here is why it is important to moldproof items and how to protect your investment with our products.

1. Impact of Mold

Mold not only grows quickly, but also causes damage to a variety of items, including clothing, books, furniture, and electronic devices. The presence of mold can cause items to mold, discolor, and even rot, making them unusable.

2. Health Risks

Spores released by mold can be inhaled into the body and may cause allergies, respiratory problems, and other health risks. Especially for people with asthma or other respiratory diseases, the presence of mold is a potential threat.

3. Financial Loss

Items that are affected by mold not only need to be cleaned and repaired, but may also need to be replaced in severe cases. This will lead to additional financial losses. Therefore, investing in moldproofing measures can save a lot of money in the long run.

4. Effective Mold-Proof Products

To effectively prevent mold growth, it is essential to use high-quality mold-proof materials and desiccants. Our anti-mold products, such as Anti mold packing paper, are designed to prevent mold and provide strong protection for your belongings.

5. Implement Mold-Proof Measures

You can effectively prevent mold growth by taking the following measures:

- Use desiccants in humid environments, especially our desiccant products, which can effectively absorb moisture and keep items dry.

- Clean and inspect items regularly.

- Ensure that storage spaces are well ventilated.

- Choose mold-proof materials to pack products.

Protecting your belongings from mold is essential, both to extend the life of the items and to maintain the health of you and your family. The professional mold-proof solutions provided by TOPONE Anti-mold Material Co., Ltd. will help you effectively resist the threat of mold. Choose our products to make your living space safer and fresher!

Why mold prevention is important in our daily life?

Mold is a common microorganism that reproduces rapidly in a humid environment, posing a serious threat to our health, belongings, and even property. TOPONE Anti-mold Material Co., Ltd. specializes in the mold prevention and desiccant industry and is committed to providing effective mold prevention solutions. Understanding the harm of mold will help you realize the necessity of mold prevention measures and provide you with effective means to protect your products.

1. Health hazards of mold

Once mold spores enter the air, they are inhaled by people and may cause health problems such as allergies, asthma, and respiratory infections. Especially in the case of long-term exposure, mold can aggravate the onset of respiratory diseases and may even cause serious health crises. For people with weak immunity, the threat of mold is even more obvious.

2. Damage to objects

Mold not only affects human health, but also seriously damages homes and objects. When mold grows on items such as furniture, clothing, books, leather products, or electrical appliances, it can cause these items to mold, discolor, corrode, or even completely damage them. These damages are often irreversible, especially for expensive items, where the losses caused by mold are even greater.

3. Expansion of economic losses

The growth of mold not only causes damage to items, but can also bring huge economic burdens. For example, mold infestations in homes can require expensive cleaning, repairs, or even replacement of damaged items. For places such as companies, factories, or warehouses that require large-scale storage of items, the damage caused by mold can lead to serious economic losses.

4. How to prevent mold: solutions

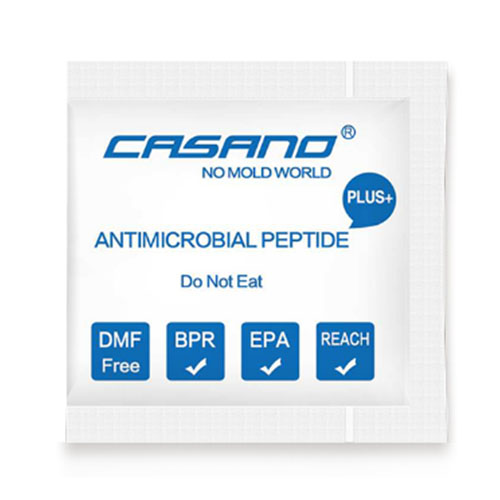

To prevent the growth of mold, it is essential to take appropriate anti-mold measures. TOPONE Anti-mold Material Co., Ltd. offers a range of professional anti-mold products, such as antimicrobial peptide plus and warehouse desiccant bag, which can effectively prevent mold growth and keep the environment and items dry and clean.

Antimicrobial Peptide Plus: This product has strong anti-mold properties and can be used to treat a variety of items to prevent mold growth and ensure the long-term preservation of items.

Warehouse Desiccant Bag: This highly effective desiccant can quickly absorb moisture from the air, keeping the warehouse and storage environment dry, thereby effectively preventing the growth of mold.

5. How to protect your items

By using our professional anti-mold and drying products, you can effectively extend the service life of your items and reduce the damage of mold to your items. Regularly check the storage environment, keep it ventilated and dry, and use products such as Antimicrobial Peptide Plus and warehouse desiccant bag to effectively prevent mold growth and keep your items intact.

The harm of mold cannot be ignored. It not only threatens health, but also causes damage to items and property. Taking effective anti-mold measures is the key to ensuring the safety of health and items. The professional anti-mold products provided by TOPONE Anti-mold Material Co., Ltd. can help you stay away from mold damage and protect your health and property. Choose our anti-mold solutions to make your living and working environment healthier and fresher!

Polyacrylamide (PAM) is a synthetic polymer that finds applications in various industries and fields due to its unique properties. Some successful application cases of polyacrylamide include:

1. Water Treatment: Polyacrylamide is widely used in water treatment processes as a flocculant, assisting in the removal of solid particles and turbidity from water. It is effective in treating wastewater from industries such as papermaking, mining, oil and gas, and municipal sewage treatment plants.

2. Enhanced Oil Recovery (EOR): In the oil and gas industry, polyacrylamide is used in enhanced oil recovery processes. It helps in improving the flow of oil by increasing the viscosity of injected water, which displaces more oil from the reservoir and enhances overall oil recovery.

3. Soil Erosion Control: Polyacrylamide is used in soil erosion control measures such as erosion control blankets and sediment basins. When applied to the soil, it can improve its structure, reduce water runoff, and prevent soil erosion.

4. Agriculture: Polyacrylamide is used in agriculture to improve soil quality, increase water retention, and reduce soil erosion. It can enhance irrigation efficiency by reducing water loss due to runoff.

5. Papermaking: In the paper industry, polyacrylamide is used as a retention aid and drainage aid. It improves the retention of fine particles during the papermaking process and enhances water drainage, resulting in improved paper quality and increased production efficiency.

6. Mining: Polyacrylamide is used in mineral processing, particularly in thickening, dewatering, and tailings management. It aids in the clarification and separation of minerals from water and assists in the dewatering of mining slurries.

7. Textile Industry: Polyacrylamide is employed in the textile industry as a sizing agent and fabric finishing agent. It helps to improve the strength and smoothness of fabrics, enhancing their quality and appearance.

8. Construction and Cement: In construction, polyacrylamide is used as a binder in the formulation of cement and concrete. It improves the workability and strength of concrete, reduces water permeability, and prevents cracking.

9. Cosmetics: Polyacrylamide derivatives are used in cosmetic formulations such as creams, lotions, and gels as thickeners, stabilizers, and texture enhancers.

These are just a few examples of the successful applications of polyacrylamide. Its versatility, water-solubility, and ability to modify flow properties make it valuable across industries.

If you’re new to the world of plastics and looking to work with Best Price Raw Material PA 6 Nylon6 High Impact Plastic Pellets, you’ve come to the right place. In this step-by-step guide, we’ll walk you through the process of using these pellets to create durable and high-impact plastic products. Let’s get started!

Step 1: Familiarize Yourself with PA 6 Nylon6

Before diving into the specifics of using the plastic pellets, it’s important to understand the characteristics and benefits of PA 6 Nylon6. This type of plastic is known for its exceptional strength, toughness, and resistance to impact. It is widely used in various applications, including automotive parts, electrical connectors, and consumer goods.

Step 2: Gather the Required Materials

To begin with, gather all the necessary materials for the plastic molding process. This includes Best Price Raw Material PA 6 Nylon6 High Impact Plastic Pellets, molding equipment (such as an injection molding machine or extruder), molds, and any additional additives or colorants you may want to incorporate.

Step 3: Prepare the Plastic Pellets

Before using the pellets, it’s crucial to ensure they are clean and free from any contaminants. If necessary, run the pellets through a dry air hopper dryer to remove any moisture. This step is important to prevent defects in the finished product.

Step 4: Set Up the Molding Equipment

Follow the manufacturer’s instructions to properly set up your molding equipment. This includes adjusting the temperature, pressure, and other settings to suit the PA 6 Nylon6 plastic pellets. Make sure all safety precautions are taken during equipment setup.

Step 5: Load the Plastic Pellets

Once your equipment is ready, carefully load the Best Price Raw Material PA 6 Nylon6 High Impact Plastic Pellets into the hopper of the machine. Use a funnel or scoop to avoid spillage and ensure accuracy. Ensure that the pellets are evenly distributed within the hopper.

Step 6: Start the Molding Process

With the plastic pellets loaded, activate the molding machine to begin the process. Monitor the temperature and pressure to ensure proper melting and molding of the plastic. Adjust any settings as necessary for optimal results.

Step 7: Cool and Remove the Molded Product

Once the plastic material has solidified in the mold, allow it to cool down completely. This may take a few minutes or longer, depending on the size and complexity of the product. Once cooled, carefully remove the molded product from the mold.

Step 8: Post-Processing (if necessary)

Depending on your specific requirements, you may need to perform additional post-processing steps. This could include trimming excess material, sanding rough edges, or adding any desired finishing touches.

Step 9: Inspect and Test the Final Product

Before the plastic product is considered complete, thoroughly inspect it for any defects or imperfections. Perform any necessary tests to ensure it meets the desired specifications in terms of strength, impact resistance, and overall quality.

By following these step-by-step instructions, you can confidently use Best Price Raw Material PA 6 Nylon6 High Impact Plastic Pellets to create durable and high-quality plastic products. Remember to always prioritize safety and carefully follow the manufacturer’s guidelines throughout the entire process. Happy molding!

When it comes to plastic structured packing, one component stands out for its remarkable efficiency and versatility: the honeycomb shape plastic support block. These small yet powerful blocks play a crucial role in enhancing the performance and durability of structured packing systems. Whether you are a seasoned enthusiast or just starting your journey into plastic structured packing, this post is here to guide you through some invaluable tips and tricks for making the most of honeycomb shape support blocks.

1. Understand the Purpose

Before diving into the tips and tricks, let’s first understand the purpose of honeycomb shape support blocks. These blocks act as a vital support structure, providing stability and maintaining the shape of the structured packing layers, ensuring even distribution of gas and liquid flow. By preventing excessive movement or compression of the packing layers, they optimize efficiency and minimize pressure drop.

2. Choose the Right Material

Selecting the appropriate material for your honeycomb shape support blocks is fundamental. Different applications require specific characteristics like chemical resistance, temperature resistance, and mechanical strength. Common materials include polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC). Assess your requirements and consult with experts or suppliers to find the perfect match.

3. Optimize Block Density

The density of the honeycomb shape support blocks plays a vital role in overall system performance. Higher block density provides enhanced stability and prevents deformation of the packing layers. However, denser blocks can also increase pressure drop. Finding the right balance depends on factors such as tower size, column pressure, and flow rates. Experimentation and careful observation will help you strike the optimal density for your system.

4. Ensure Proper Block Orientation

When placing honeycomb shape support blocks, pay attention to their orientation. Proper orientation ensures that the blocks provide maximum support and promote optimal liquid and gas distribution. Align the blocks vertically, with the opening facing downwards to allow for efficient flow through the structured packing layers. This ensures even distribution, avoiding preferential flow paths and channeling.

5. Achieve Uniformity in Block Distribution

Uniform distribution of honeycomb shape support blocks is vital for achieving consistent and efficient performance. Avoid clumping or placing too many blocks in one area, as this can lead to uneven flow distribution and decreased efficiency. Distribute the blocks evenly throughout the column to ensure balance, prevent dead zones, and maintain uniform liquid and gas contact.

6. Regular Maintenance and Cleaning

To prolong the lifespan and efficiency of your honeycomb shape support blocks, regular maintenance is essential. Periodically inspect the blocks for any signs of damage, wear, or blockage. Clean them thoroughly using suitable chemicals or solvents, following the manufacturer’s instructions. Proper maintenance will not only optimize performance but also reduce the possibility of contamination and clogging.

7. Evaluate Performance and Adjust

Structured packing systems are highly customizable, and optimizing their performance involves trial and error. Monitor and evaluate the performance of your system regularly, assessing factors such as pressure drop, separation efficiency, and liquid holdup. If necessary, make adjustments to parameters like block density, orientation, and distribution to achieve the desired outcome.

By following these tips and tricks, you can unlock the true potential of honeycomb shape plastic support blocks in your structured packing system. Remember, each system is unique, so it’s important to experiment and fine-tune based on your specific requirements. Embrace the versatility of honeycomb shape support blocks and enjoy the enhanced efficiency and performance they bring to your plastic structured packing adventures!

Dcover the Versatility of Polyethylene (PE) Foam Tape

What is Polyethylene (PE) Foam Tape?

Polyethylene (PE) Foam Tape is a durable and flexible adhesive tape made from closed-cell polyethylene foam. It offers excellent cushioning, insulation, and sealing properties, making it ideal for a wide range of applications in various industries.

Key Benefits of PE Foam Tape

- Excellent Adhesion: The strong adhesive ensures a secure bond on various surfaces, including metal, plastic, and glass.

- Weather Resistance: PE Foam Tape is resistant to moisture, UV rays, and extreme temperatures, making it suitable for both indoor and outdoor use.

- Sound and Vibration Dampening: Its cushioning properties help reduce noise and vibration, enhancing comfort in applications like automotive and construction.

- Easy to Cut and Apply: The tape can be easily cut to desired lengths and applied without the need for special tools.

Applications of PE Foam Tape

- Automotive Industry: Used for bonding trim, weather stripping, and soundproofing.

- Construction: Ideal for sealing windows, doors, and insulating panels.

- Electronics: Provides cushioning and protection for delicate components.

- General Manufacturing: Perfect for packaging and assembly processes.

Why Choose Our PE Foam Tape?

Our PE Foam Tape is manufactured to the highest standards, ensuring quality and reliability. Whether you need a small roll for a DIY project or bulk quantities for industrial use, we have the right solution for you. Additionally, our double sided foam tape provides an extra layer of versatility, making it perfect for applications requiring double-sided adhesion.

Polyethylene (PE) Foam Tape is a versatile solution for many applications, providing durability, flexibility, and ease of use. Explore our range of PE Foam Tape today and discover how it can enhance your projects!

A Versatile Solution for All Your Adhesive Needs

In today's industrial and home applications, choosing the right adhesive is crucial. Acrylic foam tape is a highly reliable choice, widely favored for its excellent performance and versatility.

What is Acrylic Foam Tape?

Acrylic Foam Tape is a double-sided tape made from acrylic foam material, known for its superior bonding capabilities. Its thickness and flexibility make it suitable for various surfaces, providing outstanding adhesion on smooth metals, plastics, and rough wood.

Key Advantages

-

Strong Adhesion: Acrylic foam tape maintains its bonding performance under extreme temperatures and humidity, suitable for both indoor and outdoor environments. This makes it a great option for high strength acrylic tape applications.

-

Weather Resistance: This tape boasts excellent UV and chemical resistance, ensuring it won't degrade in various conditions.

-

Shock and Sound Absorption: The foam structure effectively absorbs vibrations and sound, making it ideal for applications in the automotive and construction industries.

-

Easy to Use: No specialized tools are required; simply peel and apply for quick and convenient use.

Applications

Acrylic Foam Tape is widely used in multiple industries, including:

- Automotive: For sealing and bonding windows, doors, and other components.

- Construction: Used in the installation and insulation of walls and windows.

- Electronics: For securing and insulating components, ensuring circuit stability.

- Home Goods: Ideal for wall decoration and furniture bonding.

Choosing Acrylic foam tape not only enhances work efficiency but also ensures product quality and durability. Whether you are a business user or a DIY enthusiast, Acrylic foam tape is an ideal adhesive solution.

Visit our website now to learn more about Acrylic foam tape and get a quote for your custom needs!

- Bismaleimide Series2

- Cross-Linking agent / Vulcanizing Agent1

- Curing Agent1

- Engineering Plastic Pellets4

- Epoxy Resin1

- Ethylene-VinylAlcohol Copolymer(EVOH)1

- Fish Oil1

- Food Additives3

- Glucosamine1

- Heat-resistant modifier series1

- High Assay Quaternary Ammonium Compounds9

- Low Assay Quaternary Ammonium Compounds13

- Modified Polyvinyl Alcohol1

- Monomalemide Series2

- Other Surfactants/Catalysts3

- Plastic Random Packing1

- Plastic Structured Packing1

- Polyacrylamide1

- Polyurethane Resin2

- Polyvinyl Alcohol (PVA)2

- Power Coatings3

- Quaternary Ammonium Hydroxide4

- Special Quaternary Ammonium Compounds7

- TPU4

- Tertiary Amines1

- UV Ink1

- VAE Emulsion (Vinyl Acetate–ethylene Copolymer Emulsion)1

- antiform1

- fire sleeve2

- resin1