Polysorbate 20

Polysorbate 20, also known as Tween 20, is a non-ionic surfactant. Its chemical structure is composed of the condensation of anhydrous sorbitol monolaurate with ethylene oxide.

Properties:

1. Water solubility: Good

2. Appearance: Clear liquid, colorless to pale yellow at room temperature

3. Odor: Slightly smelly

4. Emulsification ability: Strong

5. Skin irritation: Relatively low

Polysorbate 60

Polysorbate 60, also known as Tween 60, is formed by the condensation of anhydrous sorbitol monostearate with ethylene oxide.

Properties:

1. Water solubility: Good

2. Appearance: Yellow to orange oily liquid or semi-solid

3. Odor: Slightly smelly

4. Emulsification, dispersion, and stabilizing properties: Exhibits various performance in different applications

Polysorbate 80

Polysorbate 80, also known as Tween 80, is produced by the condensation of anhydrous sorbitol monooleate with ethylene oxide.

Properties:

1. Appearance: Viscous liquid, yellow to orange

2. Odor: Slightly smelly

3. Taste: Slightly bitter

4. Emulsification ability: Strong, especially suitable for high oil-phase products

Differences in the Application of Polysorbates 20, 60, and 80

In Cosmetics

Polysorbate 20: Commonly used in lightweight skincare products such as toners and serums. It helps active ingredients disperse better in water, making the product lighter and more easily absorbed by the skin.

Polysorbate 60: Used more in emulsions like lotions and creams. It helps to better integrate the oil and water phases, forming stable emulsions and improving texture and feel.

Polysorbate 80: Due to its strong emulsifying ability, it is often used in cosmetics with a high oil-phase content.

In the Food Industry

Polysorbate 20: Used in beverages, juices, etc., for emulsification and stabilization, ensuring the even dispersion of ingredients and preventing separation or sedimentation.

Polysorbate 60: In foods like ice cream and pastries, it improves texture and taste, enhancing emulsification.

Polysorbate 80: Often used in the preparation of edible oils, flavor emulsions, etc., to improve stability and uniformity.

In Pharmaceuticals

Polysorbate 20: Used as a solubilizer and emulsifier.

Polysorbate 60: Enhances the release and absorption of drugs.

Polysorbate 80: Can increase bioavailability.

Can Polysorbates 20, 60, and 80 Be Substituted for One Another?

Generally, Polysorbates 20, 60, and 80 cannot be substituted for each other.

While they are all non-ionic surfactants with similar chemical structures, the differences in the length and structure of their fatty acid chains result in distinct emulsifying, dispersing, and stabilizing properties. In different applications, the requirements for surfactant performance can vary.

In the pharmaceutical field, the selection of surfactants is more stringent, and substituting one for another could affect the drug’s solubility, stability, and bioavailability, potentially leading to adverse effects.

In conclusion, there are significant differences in the chemical structure, properties, and applications of Polysorbates 20, 60, and 80. They should not be simply substituted for one another. In practice, the appropriate type of Polysorbate should be selected based on specific product needs and performance requirements.

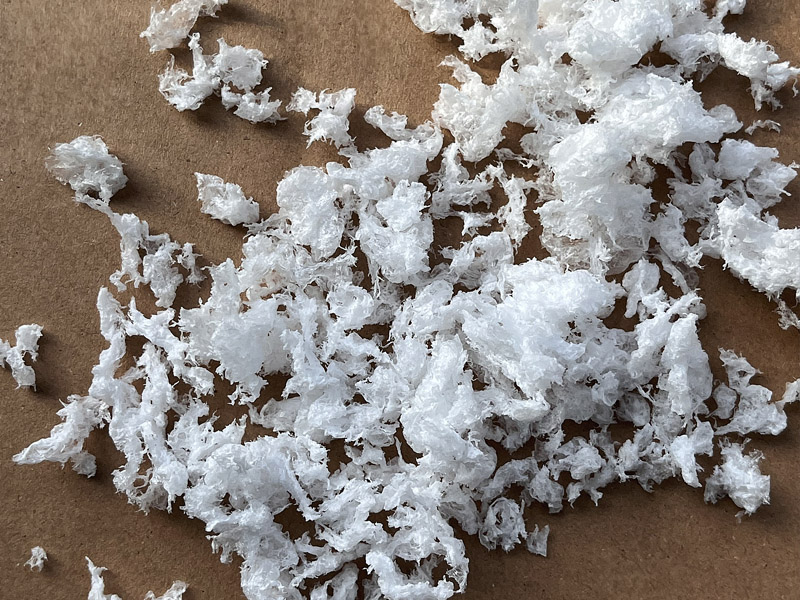

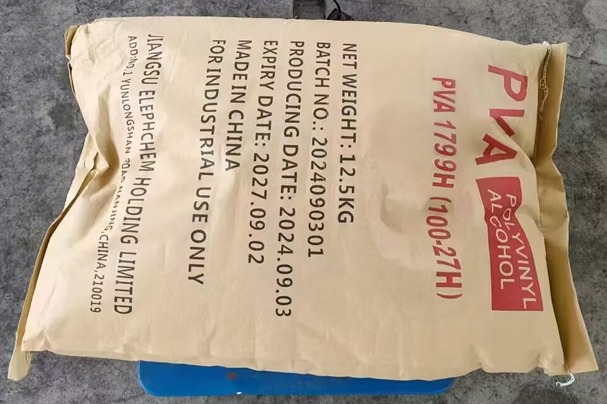

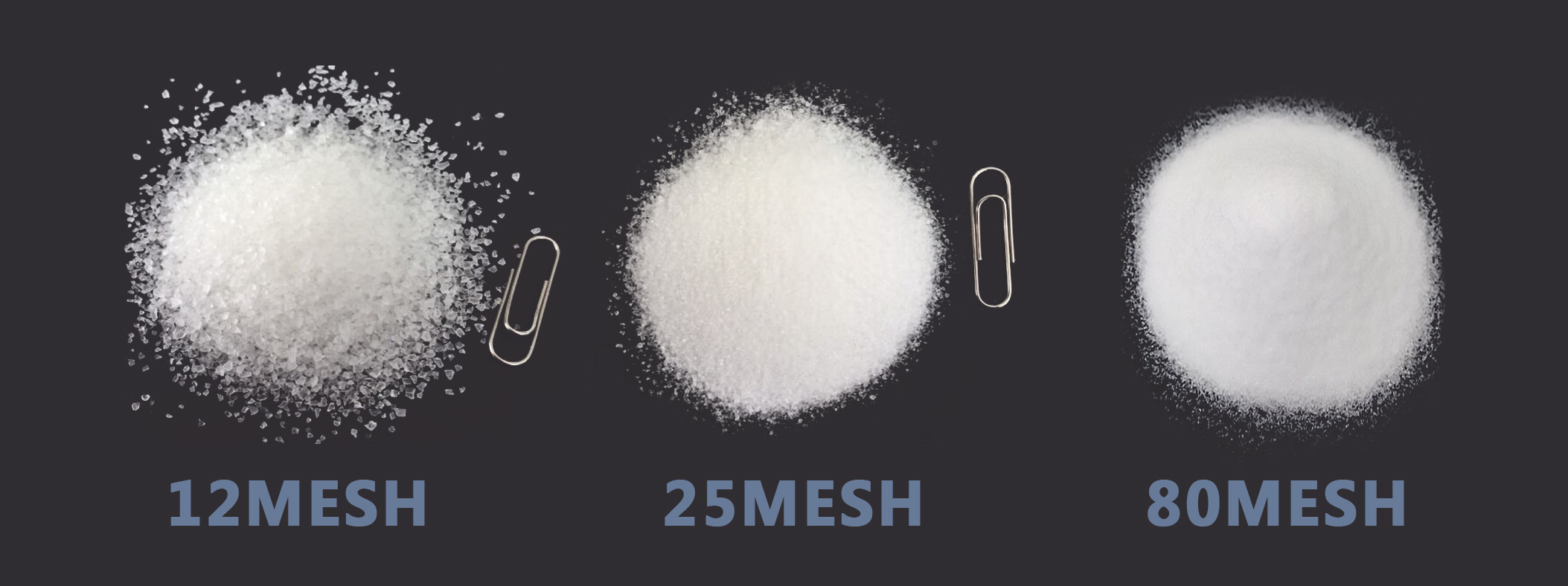

Temperature plays a significant role in the PVA dissolution process. Higher temperatures generally accelerate the dissolution rate due to increased molecular motion and higher kinetic energy. However, excessively high temperatures can lead to the degradation of PVA, affecting its performance. It is recommended to maintain the temperature within a suitable range for optimal dissolution without compromising the integrity of the polymer. Elephchem can provide polyvinyl alcohol in different mesh sizes.

Temperature plays a significant role in the PVA dissolution process. Higher temperatures generally accelerate the dissolution rate due to increased molecular motion and higher kinetic energy. However, excessively high temperatures can lead to the degradation of PVA, affecting its performance. It is recommended to maintain the temperature within a suitable range for optimal dissolution without compromising the integrity of the polymer. Elephchem can provide polyvinyl alcohol in different mesh sizes.