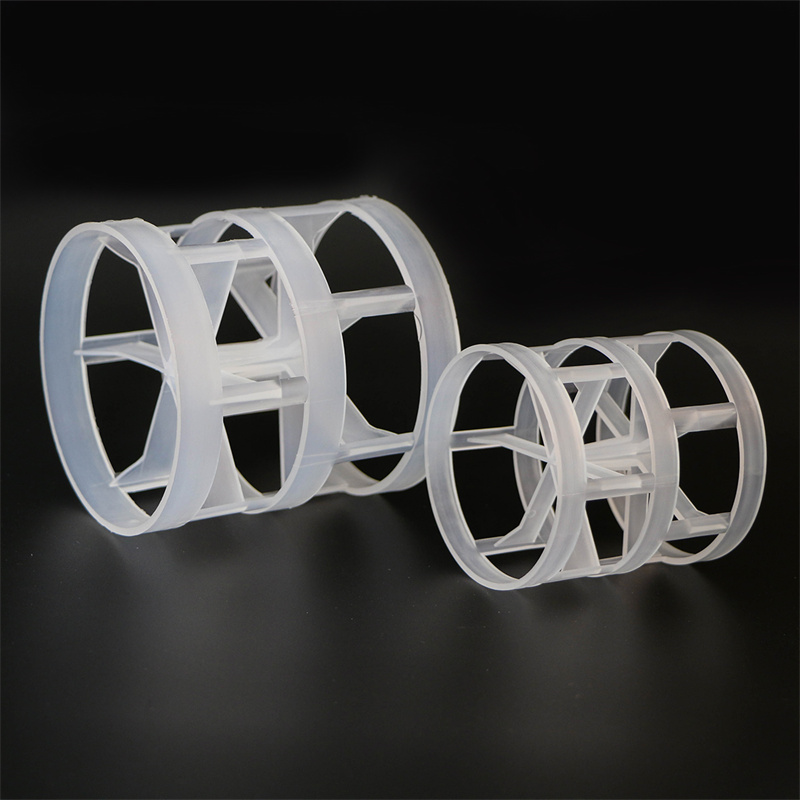

Pall rings and Intalox saddles are both types of random packing used in industrial processes to enhance mass transfer in packed columns. However, they differ in design, performance characteristics, and specific applications. Here’s a detailed comparison:

Design:

-

Pall Rings:

Shape: Cylindrical with an open structure and internal struts.

- Surface Area: Provides a high surface area due to the internal and external geometry.

- Material: Made from metal, plastic, or ceramic.

Intalox Saddles:

-

- Shape: Saddle-shaped with a contoured surface and open structure.

- Surface Area: Offers a large surface area due to the saddle shape.

- Material: Typically made from ceramic, plastic, or metal.

Performance Characteristics:

-

Pall Rings:

- Efficiency: High mass transfer efficiency due to excellent gas-liquid contact.

- Pressure Drop: Low pressure drop, making them energy-efficient.

- Capacity: High capacity for gas and liquid flow.

- Mixing: Promotes turbulent flow, enhancing mixing and mass transfer.

-

Intalox Saddles:

- Efficiency: High mass transfer efficiency with good gas-liquid distribution.

- Pressure Drop: Very low pressure drop, even lower than pall rings.

- Capacity: High capacity, often higher than pall rings.

- Mixing: Provides uniform liquid distribution and good mixing.

Applications:

-

Pall Rings:

- Suitable for a wide range of applications, including distillation, absorption, and stripping.

- Often used in processes requiring high efficiency and low pressure drop.

-

Intalox Saddles:

- Ideal for applications requiring very low pressure drop and high capacity.

- Commonly used in distillation, absorption, and other mass transfer operations, especially in processes where minimizing energy consumption is critical.

Advantages:

-

Pall Rings:

- Robust design with high durability.

- Versatile and suitable for various industries and processes.

-

Intalox Saddles:

- Excellent liquid distribution and low pressure drop.

- High capacity and efficiency, making them suitable for large-scale operations.

Summary:

While both pall rings and Intalox saddles are effective in enhancing mass transfer, the choice between them depends on specific process requirements. Pall rings are known for their robustness and versatility, while Intalox saddles are preferred for their superior liquid distribution and extremely low pressure drop. Selecting the appropriate packing can optimize process efficiency and reduce operational costs.

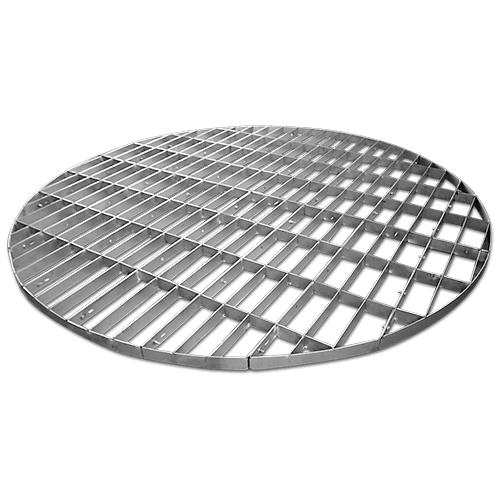

Support Plate:

-

Design:

- Flat or slightly curved plates with openings (holes, slots, or grids) to allow the passage of gas and liquid.

- Typically made from metal, plastic, or composite materials.

-

Function:

- Primary Role: To provide a stable base for the packing material and distribute the weight evenly.

- Flow Distribution: Ensures uniform distribution of gas and liquid across the packing bed.

- Drainage: Allows liquid to drain effectively while preventing excessive hold-up or flooding.

-

Applications:

- Used in both random and structured packing systems.

- Suitable for a wide range of industries, including chemical, petrochemical, and environmental.

-

Advantages:

- Simple and robust design.

- Provides excellent support and drainage capabilities.

Hump Support:

-

Design:

- Curved or arched plates with a "hump" shape, often with openings for gas and liquid flow.

- Made from materials such as metal or plastic.

-

Function:

- Primary Role: To support the packing material while minimizing pressure drop and improving liquid distribution.

- Enhanced Drainage: The hump shape facilitates better liquid drainage and reduces the risk of liquid pooling.

- Gas Flow Optimization: The design allows for smoother gas flow, reducing resistance and energy consumption.

-

Applications:

- Commonly used in columns with high liquid flow rates or where minimizing pressure drop is critical.

- Ideal for applications involving random packing.

-

Advantages:

- Improved liquid and gas distribution compared to flat support plates.

- Lower pressure drop, leading to energy savings.

- Reduces the risk of flooding and channeling.

Key Differences:

-

Design:

- Support plates are typically flat or slightly curved, while hump supports have a distinct arched or hump-like shape.

-

Pressure Drop:

- Hump supports are designed to minimize pressure drop more effectively than flat support plates.

-

Liquid Drainage:

- Hump supports offer better liquid drainage due to their arched design, reducing the risk of liquid hold-up.

-

Application Specificity:

- Support plates are more versatile and widely used, while hump supports are often chosen for specific applications requiring optimized flow and drainage.

Comparison Summary:

| Feature | Support Plate | Hump Support |

|---|---|---|

| Shape | Flat or slightly curved | Arched or hump-shaped |

| Pressure Drop | Higher compared to hump supports | Lower |

| Liquid Drainage | Good | Excellent |

| Applications | General-purpose, wide range | High liquid flow, low pressure drop |

Polyvinyl Alcohol (PVA The market for Polyvinyl Alcohol has grown significantly in recent years, thanks to its wide range of applications. The demand for PVA is driven by its use in sectors such as adhesives, textiles, paper, packaging, construction, and pharmaceuticals. The global market for Polyvinyl Alcohol is expected to witness steady growth due to the increasing adoption of eco-friendly and sustainable materials in various industries. Polyvinyl Alcohol is widely used as a binder in adhesive formulations due to its excellent adhesion properties. Its application in industries such as woodworking, packaging, and labels presents significant growth opportunities. The more commonly used grades are 2488 When it comes to the textile industry for various purposes, including sizing agents, warp yarn lubricants, and fiber modification. The increasing demand for eco-friendly textile materials and the growing emphasis on sustainable production methods provide ample opportunities for PVA in this sector. Especially in some developing countries where the textile industry is prevalent. The annual demand for PVA 1788 With its strong binding capabilities, PVA is extensively used in the paper industry. It enhances the strength and quality of paper products, leading to improved printability and durability. The rising demand for high-performance paper products and the emphasis on recyclability drive the market for PVA in this sector. The development of flexible packaging materials has gained traction in recent years. PVA-based films The future of Polyvinyl Alcohol looks promising. As industries continue to prioritize sustainability and environmental concerns, PVA's biodegradability and non-toxic nature make it an attractive choice. Additionally, ongoing research and development efforts aim to enhance the properties and expand the application scope of PVA, opening doors for novel uses in areas such as biomedicine, food, cosmetics, and 3D printing.

Polyvinyl butyral (PVB In the automotive sector, PVB is used as an interlayer PVB films The PVB market has witnessed substantial growth in recent years, driven by increasing demand for safety and energy-efficient solutions across industries. In the automotive sector, stringent safety regulations and rising consumer awareness have boosted the adoption of laminated glass, thereby driving the demand for PVB. Similarly, the growing emphasis on sustainable construction practices has fueled the demand for PVB in the architectural industry, where energy-efficient glazing solutions are sought after. Moreover, the expanding solar energy sector has presented opportunities for PVB in photovoltaic applications. The advancements in solar cell technology and the shift towards renewable energy sources have increased the demand for PVB as a reliable encapsulation material. The future of the PVB market looks promising, with several factors contributing to its growth. The increasing focus on safety and environmental sustainability will continue to drive demand for PVB in automotive and architectural applications. The growing urbanization and infrastructure development across regions also present significant opportunities for the PVB market. Furthermore, advancements in PVB technology, such as the development of new formulations and improved performance characteristics, are expected to expand the scope of PVB applications. Manufacturers are investing in research and development to enhance the properties of PVB, including its optical clarity, adhesion, and resistance to yellowing over time. Website: www.elephchem.com Whatsapp: (+)86 13851435272 E-mail: admin@elephchem.com

The full name of PVB is polyvinyl butyral, or PVB resin There are three main synthesis methods for producing PVB in the industry: one-step method, dissolution method and precipitation method. The following will introduce these three process methods and their advantages and disadvantages in the production process one by one. The one-step method refers to a generation process in which the hydrolysis of polyvinyl acetate (PVAC The dissolution method is to make PVA into a methanol suspension, add HCI and butyraldehyde to perform a condensation reaction. As the reaction proceeds, PVA gradually dissolves to form a uniform solution. After reaching the specified acetal ratio, it precipitates in water. After washing, neutralizing and drying, the finished PVB product can be obtained. The acetal rate of the PVB resin produced by this method can reach more than 86%, and the condensation distribution is uniform. The precipitation method requires first dissolving PVA in water (85-90°C), then filtering the solution, pressing it into an acetal kettle, adding hydrochloric acid and butyraldehyde, and adding butyraldehyde in two batches to start homogeneous condensation. When the reaction reaches a certain level, PVB particles are precipitated from the solution and suspended in the mother liquor, which is a heterogeneous condensation reaction. When the condensation is completed, the material is put into a water washing kettle, washed with water, and alkali is added for stabilization, then filtered and dried to obtain powdered PVB. Website: www.elephchem.com Whatsapp: (+)86 13851435272 E-mail: admin@elephchem.com

Polyvinyl Butyral One of the key characteristics of PVB is its high transparency. PVB films PVB exhibits remarkable adhesion to various substrates, including glass, metals, and plastics. This adhesive property makes it an ideal interlayer material for laminated safety glass. The strong bond created by PVB interlayers holds the glass together even when it breaks, thus providing enhanced protection against personal injury and property damage. The adhesion of PVB also makes it suitable for laminating other materials, such as textiles, metals, and electronic components. When used as an interlayer in laminated glass, PVB significantly improves impact resistance. The tough and flexible nature of PVB helps absorb and distribute energy upon impact, minimizing the risk of breakage. This impact-resistant property finds applications in safety glass for automotive windshields, architectural structures, and bullet-resistant glass. PVB exhibits excellent resistance to ultraviolet (UV) radiation. It acts as a UV stabilizer, protecting the underlying materials from degradation caused by prolonged exposure to sunlight. This makes PVB an ideal choice for outdoor applications, such as solar panels and architectural glazing, where UV resistance is crucial. PVB can be customized and modified to suit specific application requirements. By altering the molecular weight and modifying the plasticizers, various grades of PVB with different characteristics can be produced. This versatility enables manufacturers to tailor PVB properties such as viscosity, glass transition temperature, and adhesion strength to meet the specific needs of different industries, including automotive, construction, and electronics. Website: www.elephchem.com Whatsapp: (+)86 13851435272 E-mail: admin@elephchem.com

Car cleaning agent - as an early maintenance product, in the car beauty shop, the staff will use the car cleaning agent. Car cleaning agent can not only clean the dust on the surface of the car body, but also form a film to protect the car paint. However, during the production process of car cleaning agents, excessive foam will be produced, which will seriously affect the product quality, slow down the production efficiency, and even cause pollution to the surrounding environment. The occurrence of these series of problems has made manufacturers helpless. But at this time, fortunately, there are car cleaning agent defoamers, which can solve this problem for manufacturers.

Causes of foam in car cleaning agent:

The main active component of cleaning agent is surfactant, and its main function is cleaning. The foaming phenomenon is that the surfactant is inserted into the water phase through the hydrophilic group, and the oil-philic group is inserted into the oil phase or erected in the air to form a directional arrangement on the interface layer or surface, so that the interfacial tension is reduced, which causes the air to form small bubbles in the liquid, and ensures that the bubbles rise to form the foam layer.

Hazards of foam produced by car cleaning agents:

1. For multi-porous cleaning products such as fiber products, too much foam will make it difficult to rinse clean, which will prolong the rinsing time and increase the rinsing cost.

2. Too much foam will overflow the cleaning system, leading to environmental pollution in workshops or operating places.

3. The presence of foam will affect the visibility of the cleaned surface, which is not conducive to observing the degree of cleaning on the side.

4. Too much foam will lead to unstable production and affect the quality of the product.

5. Too much foam needs to be rinsed many times, and the water consumption is large, so it is not easy to rinse.

Overview of car cleaning agent defoamer:

The car cleaning agent defoamer is made of a variety of special polyethers through a composite process, which has good defoaming and anti-foaming properties and high-shear resistance. In the transparent cleaning agent, its addition will not affect the appearance of the cleaning agent, nor will it float oil, do not break emulsion, do not float, and will not produce residual wall hanging.

Application scenarios of car cleaning agent defoamer:

Car cleaning agent defoamer is widely used in: car cleaning agent, strong alkaline water degreasing agent (equivalent to 20% NaoH solution system), pre-treatment cleaning agent (tonization process), spray electroplating cleaning agent/degreasing agent, Alkaline degreasing agent, spraying agent, degreasing agent, metal wire drawing fluid, flux, wiper water, metal cleaning agent, alkaline degreasing agent, cleaning of various metal abrasives, cleaning of special imported steel plates, aluminum, copper, zinc and magnesium parts Cleaning, cleaning of precision instruments and electronic components, EDM working fluid, etching solution, electrolyte wire cutting liquid steel plate cleaning agent, general strong acid and alkali high pressure cleaning, cutting fluid, degreasing agent, degreasing powder, degreasing of alkaline aluminum parts Powder, ordinary coating cleaning, electroplating, stainless steel cleaning, high-pressure spray cleaning, water treatment, chemical immersion and other occasions where silicone cannot be used.

How to use car cleaning agent defoamer?

antifoamchemical Car cleaning agent defoamer can be directly added to all kinds of cleaning agent liquid, its general addition amount is 0.1-1% of the total cleaning agent, the specific actual dosage should be determined by process test, it can also be mixed with other powder cleaning agent before use.

VAE emulsion VAE emulsion is a versatile adhesive solution that finds widespread application due to its excellent adhesion properties. It is commonly used in industries such as construction, woodworking, packaging, and automotive, offering a reliable bond across different substrates. One notable advantage of VAE emulsion adhesive is its ability to form strong bonds on porous materials, including wood, paper, and fabric. The formulations of VAE emulsion vary based on the protective colloids used during production, resulting in diverse properties and performance attributes. VAE emulsion is usually prepared using a medium-pressure emulsion polymerization process, with an ethylene mass fraction of 10% to 40%, generally 14% to 18%. Using different protective colloids, the structure and performance of the emulsion are different. VAE emulsion made with polyvinyl alcohol VAE emulsion adhesive boasts several noteworthy characteristics that contribute to its popularity. It often exhibits excellent film-forming properties, creating a durable and long-lasting bond. The adhesive's high solid content allows for efficient coverage and reduced drying time, making it suitable for both manual and automated applications. Additionally, VAE emulsion adhesive typically possesses low VOC (Volatile Organic Compound) levels, promoting healthier and more sustainable working environments. Beyond its traditional use as an adhesive, VAE emulsion finds innovative applications through modification processes. By introducing compatible additives or compounds, VAE emulsion adhesive can achieve specific properties tailored to unique requirements. Examples include the modification of VAE emulsion adhesives for improved heat resistance in automotive applications, enhanced water resistance in packaging applications, or increased flexibility in textile applications. These modifications broaden the range of industries and applications that can benefit from VAE emulsion adhesive.

Polyvinyl Alcohol PVA serves as an excellent adhesive for paints and coatings due to its strong bonding capabilities. It provides secure adhesion on various surfaces, including wood, metal, and plastics. Additionally, PVA glue offers good resistance to water, offering durability and longevity to the finished product. Specific like PVA 24-88 The paper making industry heavily relies on PVA adhesive for its superior binding properties. PVA plays a crucial role in paper formation, providing excellent adhesion between fibers. PVA adhesive enhances paper strength, improves printability, and reduces paper breakage during processing. For instance, like PVA 17-88 PVA adhesive finds extensive application in the woodworking industry, offering secure bonding for wood joints and assemblies. It provides strong adhesion with the ability to fill gaps and provide structural integrity to woodwork projects. Such as PVA 26-88 In the textile industry, PVA plays a vital role in various applications, including fabric sizing, finishing, and bonding. PVA adhesive provides a strong bond between different types of fabrics, enhancing the fabric's stability and durability. It is often used in textile printing, laminating, and embroidery applications due to its excellent film-forming properties. PVA adhesive ensures that textile products withstand repeated washing and retain their shape and color. One significant advantage of PVA is its water-soluble nature. This feature makes it convenient for various applications, including adhesives, films, and packaging. PVA's water solubility allows for easy cleanup and is particularly crucial in applications that require temporary adhesion or easy removal. It also makes PVA a preferred choice for water-soluble packaging materials. For example, pharmaceutical grade PVA0588 can be used to produce pharmaceutical capsule coatings. In addition to some of the applications mentioned above, PVA is also used in other industries. For example, PVA 20-88

Polyvinyl Alcohol (PVA One of the key reasons for the widespread use of Polyvinyl Alcohol is its excellent water-solubility. When dissolved in water, PVA forms a clear, transparent, and flexible film that exhibits strong adhesion to different surfaces. This property makes it invaluable in applications such as paper coatings, adhesives, and textile sizing. Polyvinyl Alcohol is often preferred due to its compatibility with a wide range of materials. It exhibits excellent adhesion to various substrates such as paper, textiles, metal, wood, and plastics. This versatility allows for its use in multiple industries, including packaging, construction, textiles, and ceramics.

- Bismaleimide Series2

- Cross-Linking agent / Vulcanizing Agent1

- Curing Agent1

- Engineering Plastic Pellets4

- Epoxy Resin1

- Ethylene-VinylAlcohol Copolymer(EVOH)1

- Fish Oil1

- Food Additives3

- Glucosamine1

- Heat-resistant modifier series1

- High Assay Quaternary Ammonium Compounds9

- Low Assay Quaternary Ammonium Compounds13

- Modified Polyvinyl Alcohol1

- Monomalemide Series2

- Other Surfactants/Catalysts8

- Plastic Random Packing1

- Plastic Structured Packing1

- Polyacrylamide1

- Polyurethane Resin2

- Polyvinyl Alcohol (PVA)2

- Power Coatings3

- Quaternary Ammonium Hydroxide4

- Special Quaternary Ammonium Compounds7

- TPU4

- Tertiary Amines1

- UV Ink1

- VAE Emulsion (Vinyl Acetate–ethylene Copolymer Emulsion)1

- antiform2

- fire sleeve2

- resin2